We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Understanding Quarrying: An Animated Guide

Did you know that every year the UK quarries over 300,000,000 tonnes of aggregates? Or that there are 1300 quarries operational around the UK today? Quarries are incredibly important to many aspects of everyday life as aggregates provide the foundation for houses, roads, shops and farms.

Not only this but a new report from the Mineral Products Association (MPA), states that four billion tonnes of crushed rock, gravel and sand will be needed over the next 15 years to meet the UK's construction needs. Every day, quarried aggregates are used to complete all kinds of projects. With all of this, it comes as no surprise the importance that quarries and quarried aggregates have in our lives.

We’ve produced this animated video to introduce you to quarrying and help you to learn a little bit more about how it works. We’ve also put together a more detailed FAQ which can be found underneath the video and will answer your most burning questions.

Quarrying FAQ

What is Quarrying?

Quarrying is the process of extracting minerals such as rocks, sand and gravel from the earth. A quarry is the place where this happens and normally looks like a deep pit. The main difference between a quarry and a mine is that a mine is underground, whilst a quarry lacks a roof; in the UK this is a legal definition but around the world, the two terms are used more loosely.

Quarried construction materials like rocks, sand and gravel are called ‘aggregates’. Dimension stones are also excavated; these are much larger and very precisely cut and finished for a particular effect. The main stone types extracted for this purpose are granite, limestone, slate, marble and sandstone.

What are aggregates used for?

The biggest use for aggregates is in construction and they are used in a huge variety of applications, including:

- - Asphalt – used for roads, pavements, runways, playgrounds etc.

- - Ready-mixed cement – created from limestone and shale

- - Drainage structures

- - Noise barriers

- - Buildings – used in foundations

- - Driveways and gardens

- - Railway ballasts

- - Reservoirs and sewage treatment works

- - Equestrian arenas

- - Concrete – a mixture of aggregates, cement and water

- - Agriculture

- - Glass – created from sand

In total, aggregates make up around 85% of all non-energy minerals extracted in the UK and are used widely in construction and industry. Dimension stones are also used in construction and are often used to construct prestigious and beautiful buildings such as monuments and official buildings. They’re also used to create kitchen countertops, gravestones, and tiles for roofs and paths.

In total, aggregates make up around 85% of all non-energy minerals extracted in the UK and are used widely in construction and industry. Dimension stones are also used in construction and are often used to construct prestigious and beautiful buildings such as monuments and official buildings. They’re also used to create kitchen countertops, gravestones, and tiles for roofs and paths.

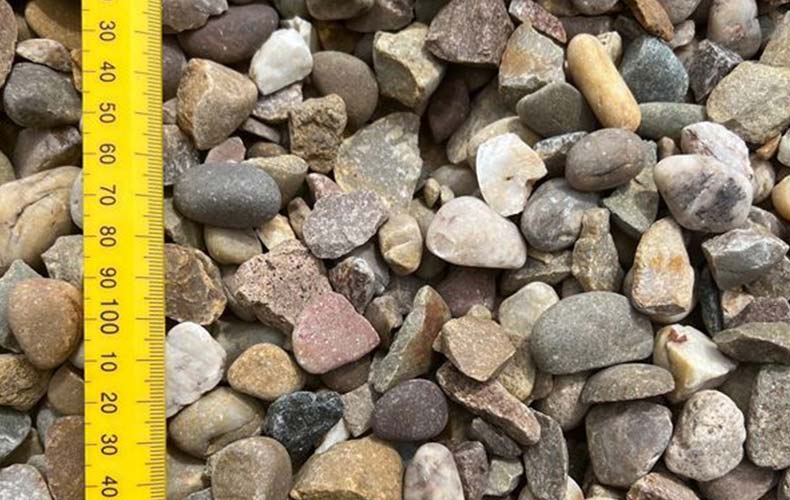

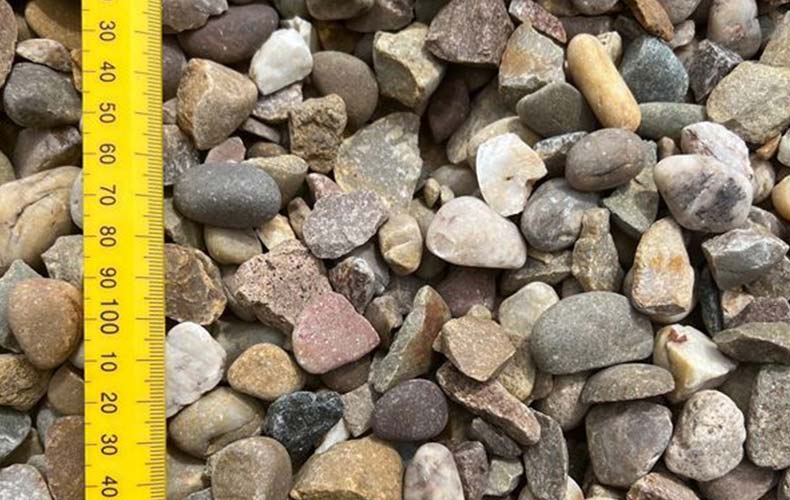

What are the most popular quarried aggregates?

At Mainland Aggregates, we supply an extensive collection of aggregates, some of our best-selling quarried aggregates include 20mm gravel and 10mm gravel. In addition to our most popular products, we can also supply MOT Type 1, MOT Type 3, rail track ballast, building sand, premium silica sand and much more.

The Quarrying Process

Drilling and Blasting

Large rock drill rigs are used to drill several holes into the rockface. These holes are then filled with explosives which are detonated to break up the rock.

Over the years, this process has become very precise, with blasts carefully timed and delivered to fragment the maximum amount of rock with the least number of blasts in order to minimise environmental impact. Blasts need to be delivered at the right time, place and in the correct quantities.

Quarries are subject to strict safety protocols. Before blasting, the area must be properly barricaded and people kept a safe distance from the blast. Quarries must also make efforts to minimise environmental impacts such as ground vibration, airblast and fumes; this can be achieved through proper blast design.

Loading and Excavating

Once the all-clear has been given, front end loaders and excavators can collect the blasted material and move it to haul trucks.

Hauling

As quarries are often in isolated areas, special haul roads often need to be built. Rigid frames and articulated lorries transport the quarried material from the quarry to the primary crusher or processing plant.

Crushing and Secondary Breaking

The blasted material isn’t fit for use initially and needs to be processed to get the correct size and quality. This normally takes place in 4 stages. The first stage uses either gyratory, jaw or impact crushers depending on the type of rock and the final product required. Later stages allow the rock to be reduced and refined to a greater extent. Secondary crushers are normally cone crushers or horizontal shaft crushers, whilst the final stages usually employ cone crushers.

Screening

Screening takes place between each stage of crushing. The most important stages are screening after primary crushing, and final screening after the last stage of crushing. Specialised screens sort the aggregates into different sizes, which can then be used in different applications.

Washing and Classifying

Aggregates are usually cleaned before they’re delivered and sold. This is to remove clay, shale, coal, soft stone, roots, twigs and other debris. During this stage, the aggregates can also be sized and classified appropriately. Dewatering equipment removes excess moisture and dirt such as slime and grit.

Quarrying and the Environment

Quarrying does bring with it environmental concerns, including noise pollution, air pollution and landscape scarification. However, in recent years efforts have been made to make the process more sustainable.

Quarry Restoration

Many disused quarries become flooded after the quarry closes. Some of these have been restored and turned into large recreational areas and nature reserves. For example, Dinmor Park Quarry in Wales was landscaped and restored, with the quarry lake transformed into a fish farm. Similarly, Tiddenfoot Waterside Park is a restored sandpit with a lake, grassland, scrub, willow woodland and a poplar foundation.

Another example is Nosterfield Nature Reserve near Ripon in Yorkshire, a former sand and gravel quarry which has been turned into wet grassland and open water; it’s now home to over 200 species of birds and waterfowl. This is a far cry from the past when quarries would have simply been abandoned!

Recycled Aggregates

Furthermore, recycled aggregates present a more sustainable solution than traditional quarries. Debris from demolition sites is crushed and screened to get the correct grade of material. By recycling concrete, brick and asphalt, there is less reliance on natural resources and therefore less damage to the environment.